Latest news

GSE reports strong interest in ink management solutions at Labelexpo Europe 2025

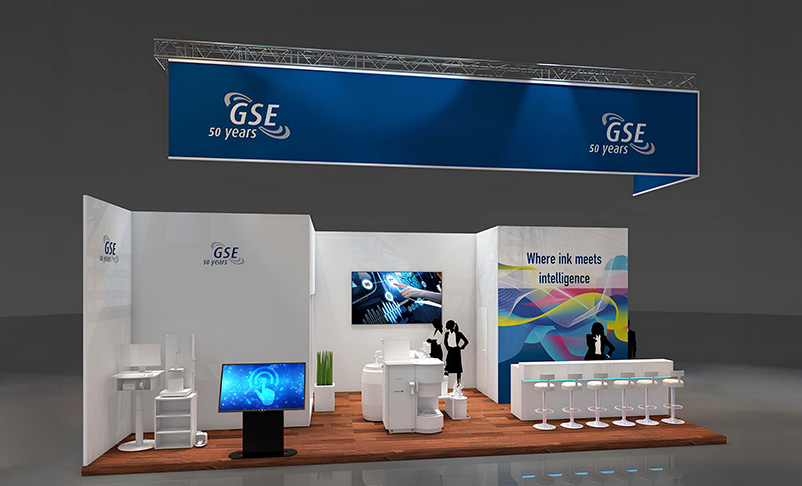

GSE presents ink dispensing and software solutions for efficient workflows and smart decision-making at Labelexpo Europe 2025

GSE’s Lean ink logistics

Muda, or ‘waste’, is a key concept in Lean. Reducing waste is the key to reducing costs and increasing profitability. We understand waste to be the deployment of all time, materials, tools, techniques, people and space in excess of what is needed to offer added value to customers.

GSE’s ink management solutions help printers to implement lean business practices that also make sound financial sense. It has helped them save up to 30 percent of their costs. By mixing base components, the dispenser eliminates the need to buy expensive ready-mixed inks and allows recycling of return inks. Stock is minimised, rework and human error are avoided and press productivity can be boosted by thousands of hours annually.

Whatever package, label or textile substrate you’re printing on, our products and software put you in total control of your ink logistics needs.

ink costs saved

systems installed

months average ROI

years of experience

Automatic ink blending

GSE’s Colormix range consists of manual, semi-automatic and automatic pneumatic blenders for the homogenization of dispensed inks in containers.

The Colorsat Compact for dispensing solvent-based inks can be integrated with an automatic roller conveyor for container transport and the automatic Colormix blender. The container is automatically positioned and grounded. The equipment features parallel dispensing and blending. The blender is turned over a container with solvent, which makes it suitable to clean the blender blades and the shaft before blending a new batch.